When selecting the right belt grinder from the 84 Engineering range we firstly need to determine the intended use for the knife grinder and how a larger or smaller belt grinder will impact the results you are after.

In the 84 Engineering range we have 2 sizes, the Shop Mate 2x48 belt grinder and the Shop Master 2x72 belt grinder, the 48 and 72 refer to the overall belt length and width.

In this case the Shop Mate uses the 2 Inch by 48 Inch belts and the Shop Master uses the 2 Inch by 72 Inch belts, the 84 Engineering Gibson is also in the 2x72" belt category.

The wider the belt the more power is required from the motor, 84 Engineering offers only a 2 inch wide platform so the motors can perform at their best, wider belts cause more friction thus requiring more power from the motor.

When using the belt grinder you often apply force to the face of the belt which increases the load on the motor, by increasing the belt length you also increase the demand on the motor.

This is why the Shop Mate uses a 1.5 horsepower motor and the Shop Master and Gibson 72 us a 2.0 horsepower motor.

All the 84 engineering range features a VFD controller (Variable Frequency Drive) this enables you to control the power output to the belt grinder, this is a fantastic feature as you can fine tune the speed to match the task you are performing.

For heavy stock removal having the belt spinning faster will speed up the process but using a slower speed with a finer belt can leave clean and accurate finishes on metal and wood.

Shop Mate 48" Grinder

The Shop Mate 2x48" Belt Grinder is orientated to someone who is a serious hobbyist or maker wanting to get into professional grade equipment, it is also a more compact unit taking up less space in your workshop or garage.

The Shop Mate is capable of handling most jobs from woodwork to metal and knife making, it also boasts a wide range of bolt on accessories from surface grinders to small wheel jigs for fine tight curves.

The Shop Mate 48” is the most compact grinder in the 84 Engineering line-up, but don’t let it’s size fool you! Equipped with an industrial 1.1kw 3 phase motor, variable speed controller, capability to run from 1/4" up to a 10” contact wheel as well as being fully compatible with our entire range of accessories – the Shop Mate offers the versatility of the larger 72” grinders on the market - without the footprint.

Shop Mate 48"

POWER

The Shop Mate grinder will plug into any standard 240v power socket. The included Variable Frequency Drive (VFD) converts power to a 3-phase signal, driving the 1.1kw motor. This setup allows you to dial in the belt speed anywhere from 0 – 4800 fpm and provides maximum motor torque even at low RPM. The VFD will automatically ramp up power when under load to maintain belt speed.

ROTATING PLATEN

The Shop Mate is equipped with a multi-function rotating platen – giving you the option of a 150mm platen, 2” contact wheel, 3” contact wheel and slack belt out of the box. Changing between these configurations is as simple as loosening the locking handle and spinning the platen – you don’t even have to remove the belt!

POLYURETHANE WHEELS

All wheels on the Shop Mate grinder are precision CNC machined from 6061 billet aluminium and coated in our newly formulated abrasion-resistant Urethane rubber. Not only does this provide excellent drive wheel traction (the belt will never slip, regardless of how much pressure you apply), but makes for quieter operation and a superior grinding experience. The rubberised wheels even out belt discrepancies meaning you will not experience any ‘jitter’ or ‘bounce’ through the contact wheels – even when using coarse-grit belts.

STABLE TRACKING

The Shop Mate’s flat-plane tracking mechanism offers increased tracking stability and ease of adjustment over many other options available on the market. The tracking is set-and-forget - just dial in tracking with the twist of a knob and it will remain true even under heavy belt load. The flat-plane tracking also allows for minimal crown/curvature of the tracking wheel meaning your j-flex and other lighter belts won't deform over time.

IN THE BOX

In the box is a fully powder-coated and assembled grinder, a fixed work rest, a tooling arm and a rotating platen – everything you need to complete most workshop fabrication tasks, wood / metal-working projects and knife shaping, sharpening and stock removal work. If you need your grinder for specific applications or simply require more versatility, a large range of compatible attachments, work rests and contact wheels are available.

PRODUCT SPECIFICATIONS

• 2 × 48” belt length

• 1.5hp 2 pole motor with 4” drive wheel

• 0 – 4800 surface feet per minute belt speed

• 6” platen

• 4 way rotating platen

• Slack belt

• 2” and 3” contact wheels

• Rubber coated wheels for smooth performance and great belt traction

• Flat plane belt tracking for accurate belt alignment

• Fully welded frame

• 3 arm slots

• Fixed work rest

• Platen arm also accepts small wheels

• Protective spark guard

• Flips from vertical to horizontal with bench or pedestal stand (sold separately)

• Made in Australia

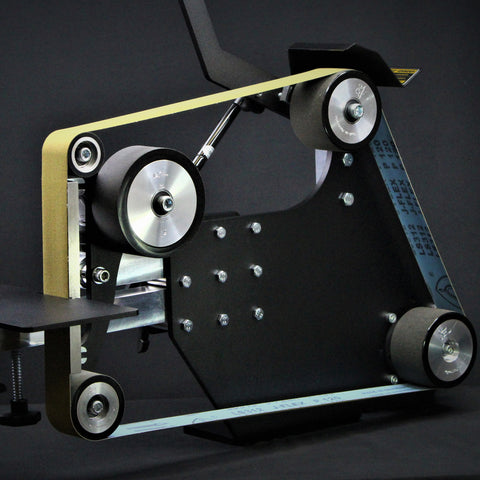

Shop Master 72" Belt Grinder

The 84 Engineering Shop Master series is the largest grinder in the range, it boasts a wide range of Accessories, Stands, Tool Rests and Tooling Arms which will enable you to handle any task you throw at it.

It also uses the same VFD as the Shop Mate 48" grinder but utilises a 2 Horsepower motor for a bit more grunt when loading the belt.

The 2x72" belt grinder has become a staple amongst Knife Makers, Fabricators, Welders, Panel Beaters, and anyone wanting a belt grinder to handle any task.

It features a long flat platen that sits behind the belt surface creating an area that you can control the accuracy of your grinds.

The main tooling arm has a infinitely adjustable swivelling contact wheel assembly that allows you to use the standard 3 sized contact wheels and platen when rotated in the correct position.

When rotating you can set either slack belt or no slack this is also controlled by the tooling arm positing in the main body of the grinder.

Both the Shop Mate and Shop Master have the ability to be mounted to a bench or floor stand that allows the grinder to lay on its side for jobs where you need better vision or just a more comfortable working position when grinding.

The Shop Master 72” Belt Grinder is designed to be a cost effective, premium machine for serious fabricators and knife makers wishing to get into the 2x72” belt size.

The sleek, single-piece folded body is laser cut from 10mm plate steel and makes for an extremely rigid yet uncomplicated chassis. All body components simply bolt together using basic hand tools, making servicing and assembly a breeze.

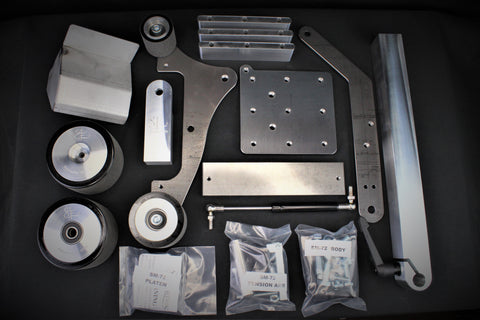

For the DIYer there is also a Shop Master 72" Kit grinder where you receive all the grinder as raw finished parts where you assemble the grinder and also paint/powder coat in any colour you desire

In the Shop Master 72" kit are all parts and fasteners required to assemble your grinder including an un-coated steel body – flat-packed in a box. Pre-wired motor and VFD are included but shipped separately due to shipping weights. Simply refer to the included instruction manual or watch our video on YouTube and see how easy it is to assemble!

Tip: we recommend customising your grinder by painting the raw steel components prior to assembly

Shop Master 72" Assembled

VERSATIILE

The Shop Master 72” grinder is one of the most versatile and easy to use machines on the market, equipped with a fixed steel work rest and a 6-in-1 rotating platen. Simply loosen the locking handle on the tooling arm and rotate the platen to change between the 215mm steel platen, a 2”, 3” & 5” rubberised contact wheel, or two different slack belt options. This design also offers ample clearance on either side of the platen making it easier to grind corners and edges on awkward work pieces.

If you require more versatility, our full range of accessories are compatible with the Shop Master 72" and can be easily swapped out via the quick-change tooling arm slots.

POWERFUL

The Shop Master grinder will plug into any standard 240v 10a power socket. The included Variable Frequency Drive (VFD) converts power to a 3-phase signal, driving the 1.5kw (2hp) motor. This setup allows you to dial in the belt speed anywhere from 0 – 4800 fpm and provides maximum motor torque even at low RPM. The VFD will automatically ramp up power when under load to maintain belt speed.

POLYURETHANE WHEELS

All wheels on the Shop Master grinder are precision CNC machined from 6061 billet aluminium and coated in our newly formulated abrasion-resistant urethane rubber. Not only does this provide excellent drive wheel traction (the belt will never slip, regardless of how much pressure you apply), but makes for quieter operation and a superior grinding experience. The rubberised wheels even out belt discrepancies meaning you will not experience any ‘jitter’ or ‘bounce’ through the contact wheels – even when using coarse-grit belts.

STABLE TRACKING

The Shop Master’s flat-plane tracking mechanism offers increased tracking stability and ease of adjustment over many other options available on the market. The tracking is set-and-forget; just dial in tracking with the twist of a knob and it will remain true, even under heavy belt load. The flat-plane tracking also allows for minimal crown/curvature of the tracking wheel, so your j-flex and other lighter belts won't deform over time.

AUTOMATIC TENSIONING

The gas strut tensioning system ensures a consistent belt tension regardless of tooling setup. The tension arm is designed to lock down when the arm is in its lowest position, allowing for effortless belt and tool changes - you can even do it single handed!

ASSEMBLY?

Due to the weight of the Shop Master, the we have broken the grinder down into 2 cartons. In one carton is a semi-assembled, powder coated body, assembled platen and drive wheel. In another box is a pre-wired motor and VFD. Simply bolt motor to the body, install the drive wheel and your grinder is ready to go

PRODUCT SPECIFICATIONS

• 2 × 72” belt length

• Pre-wired 2 hp 1.5 kW motor and VFD

• 8″ / 210mm platen - Rotating platen

• 2”,3” and 5" contact wheels

• Rubber coated wheels for smooth performance and great belt traction

• Flat plane belt tracking for accurate belt alignment

• 2 tool arm slots

• Fixed work rest

• Protective spark guard

Shop Master 72 Kit Grinder

Shop Master 72 Kit Grinder

Gibson 72" Belt Grinder

WHAT IS A GIBSON 72” Professional Belt Grinder?

This is our latest masterpiece offered up to satisfy the professional needs of artisan and industrial steel workers alike. The impressive list of features is complimented by its rigid construction, guaranteed to satisfy the demands of heavy-duty grinding projects.

RIGID CONSTRUCTION

The Gibson 72 grinder body and stand start life as 6mm Australian-made sheet steel. The components are precision laser cut before being assembled with more than 35 high-strength seam welds. Weighing in at over 85kg, the Gibson 72 is one of the most rigid and stable platforms on the grinder market. This mass and rigid construction not only ensures accuracy and perfect alignment in all grinding scenarios, but makes for a smooth, vibration-free experience.

The auxiliary components and attachments on the Gibson 72 maintain this over-engineered philosophy and premium build quality. The 40x40mm tooling arms, single-piece tension mechanism and over-sized tracking knob and are CNC machined from 6061 aluminium billet. The ergonomic tension handle and rotating platen-support are laser cut from 12mm plate steel, and over-sized 25mmØ tooling spigots and the platen rotating/indexing mechanism are turned from stainless steel bar, making for a bulletproof platform that will look great even after years of punishment.

VERSATILE

Included with every Gibson is a small wheel rest, 300x150mm chamfered angle-adjustable work rest, small wheel idler arm, ¼”, ½”, ¾” & 1” small wheel sets and an extremely versatile rotating platen. Simply loosen the locking handle and rotate the entire platen assembly to access 7 separate grinding setups! Utilise 2 x 2”, a 3” and a 5” contact wheel, a hardened 215mm D2 platen and 3 different slack belt lengths without removing a tooling arm! For consistency and ease of setup, the platen also includes a spring-loaded indexing pin that has 12 locking positions at 30-degree intervals.

Platen support design on the Gibson 72 also allows for excellent access on either side of the platen or contact wheels for un-interrupted grinding of edges, reliefs and awkward work pieces. The in-built tilting stand allows the grinder to be used in both vertical and horizontal orientations, opening a plethora of grinding configurations and unlocking the potential of attachments such as the Small Wheel Pairs.

POWERFUL

The Gibson 72” grinder will plug into any standard 240v 10a power socket. The included Variable Frequency Drive (VFD) is encased in a custom water/dust resistant enclosure and converts power to a 3-phase signal, driving the 1.5kw (2hp) 4-pole motor. This powerhouse of a setup spins a 7” drive wheel coated with high-traction 65 Shore A urethane rubber to generate a maximum belt speed of 5000 surface feet per minute. You can hog material at an epic rate or run the belt slowly enough for fine shaping, sharpening and polishing – the infinitely variable speed controller providing maximum torque throughout the 0-5000SFM speed range.

POLYURETHANE WHEELS

All contact wheels on the Gibson 72” grinder are precision CNC machined from 6061 billet aluminium and coated in our newly formulated abrasion-resistant urethane rubber. Rubberised wheels make for quieter operation and even out belt discrepancies meaning you will not experience any ‘jitter’ or ‘bounce’ through the contact wheels – even when using coarse-grit belts.

DRIVE WHEEL TRACKING

The Gibson grinder uses a unique drive-wheel tracking system whereby the whole motor mount tilts to adjust belt alignment. This design offers superior tracking characteristics, maintaining alignment under heavy belt loads and different belt tensions

INFINITE BELT TENSIONING

Another key feature of the Gibson grinder is the adjustable tensioning mechanism. The grinder tensioning mechanism uses a combination of acetyl bushes and a cam mechanism to easily and infinitely adjust your belt tension to suit the job. Simply use the ergonomic tensioning handle to tighten or loosen the belt. This feature comes in especially handy for using slack belts, and makes belt changes a quick, single-handed operation.

COMPATABILITY

As with all 84 Engineering grinders, the Gibson is compatible with our range of accessories including the popular Surface Grinder attachment. The Gibson is fully assembled in a shipping crate and is tested and fine-tuned in our workshop prior to shipping.

PRODUCT SPECIFICATIONS

•2 × 72” belt length

•2 hp 4 pole motor with 7” drive wheel for excellent belt speed and torque

•Teco E510 sealed vector variable frequency drive

•0 – 5000 surface feet per minute belt speed

•8.5” carbide faced “dovetail” platen backing

•Indexable 7 way rotating platen

•Adjustable length slack belt

•2”, 3” and 5” contact wheels

•Rubber coated wheels for smooth performance and great belt traction

•Drive wheel tracking for perfect belt alignment

•Fully welded frame

•5 arm slots

•Infinitely adjustable belt tension

•Flips from vertical to horizontal

•Large work rest with micro angle adjustment

•Pressure plates to ensure tooling arms are not damaged

•Protective spark guard

•Benchtop tilting stand

•Made in Australia

Ready to Purchase? Find the Gibson 72" Belt grinder HERE

Gibson 72" Belt Grinder