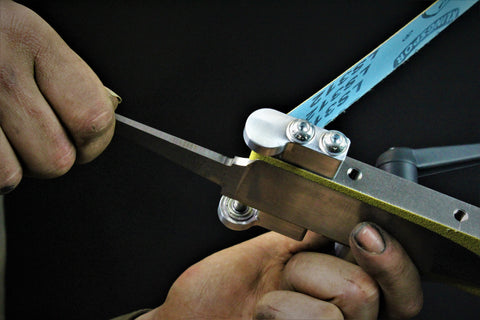

Grinding plunge lines and rounded corners on knives can be a tedious and intricate task. It requires precision, patience, and the right tools to get the job done. 84 Engineering has taken on the challenge and has come up with the solution to make knife grinding a breeze. Introducing the 84 Engineering Plunge Platens - the newest and most innovative addition to the world of knife grinding.

Our Plunge Platens use either a 6mm, 19mm, or 25mm small wheel rather than a radiused edge for reduced friction. This leads to cooler grinding and increased belt life. The minimal gap between the roller and the radiused edge of the platen ensures that the 84 Engineering radius platen will leave no transition between the wheel and 215mm flat platen, thereby reducing hand sanding to a minimum if not completely.

We recommend the 6mm Plunge Platen for thinner blades and the 19mm and 25mm for integral bolster style blades. The 19mm spigot is standard, making it easy to swap out with the included platen on either the Shop Mate 48” or Shop Master 72” belt grinders/linishers using the standard tooling arms. The Plunge Platen can also be used with a 84 Engineering small wheel arm, resting the back of the platen on the 2" idler wheel. Threaded holes on either side of the Plunge Platen allow for the spigot to be mounted to either side, giving you the option of using the Plunge Platen with the platen facing up or down, depending on your preference or application.

We recommend using light-weight J flex belts on your Plunge Platen for the best results. It is important to note that due to the size of small wheels, they should not be run at full speed on variable speed grinders. On our Shop Mate and Shop Master belt grinders, they should only be run in the slow, green zone of your speed controller.

Adjusting the 84 Engineering Plunge Platen to suit your grinder is easy. Using a 4mm Allen key, you can adjust the spigot mount to suit your grinder. You will also need to set the stop collar spacing to centre the platen to your grinder's drive and tracking wheels. A 2.5mm Allen key is required to make this adjustment. Additionally, the Plunge Platen can be inverted by moving the spigot mount to the opposite side of the platen. This is helpful for visibility while grinding.

In conclusion, the 84 Engineering Plunge Platens are the perfect addition to any knife grinder's toolkit. Designed with precision and efficiency in mind, our Plunge Platens make the otherwise tedious task of grinding plunge lines and rounded corners a breeze. Get your hands on one today and see the difference for yourself!